Understanding Common Sneeze Guard Challenges: Why Getting It Right Matters

In today’s world, where hygiene and visual appeal go hand in hand, many businesses and institutions face the age-old struggle of choosing the right sneeze guard. Whether it’s a bustling cafeteria, a self-service buffet, or a modern prep station, the installation and design of sneeze guards often become a last-minute headache—yet one that can define a customer’s perception of cleanliness and order. Have you ever walked past a serving line divided into awkward, segmented bays with metal posts blocking the view? The tension between maintaining safety standards and creating an inviting, seamless dining experience is a real and pressing concern.

The importance of sneeze guards goes far beyond just barrier protection; they represent the silent handshake of trust between the service provider and the public. But with countless designs, installation challenges, and maintenance concerns, decision-makers are left navigating a maze of options, often under time pressure. Sneeze guard systems can, if handled poorly, become sources of frustration—think costly add-ons, obstructive hardware, or slow shipping that jeopardizes opening day. Unlocking an efficient, aesthetically pleasing solution makes the difference not only in workflow but also in public confidence and the long-term perception of your environment. If you’ve ever wondered how to solve sneeze guard issues without hassle, read on for insights grounded in modern engineering and practical design philosophies.

Redefining Sneeze Guard Design: What Sets High-Performance Shields Apart

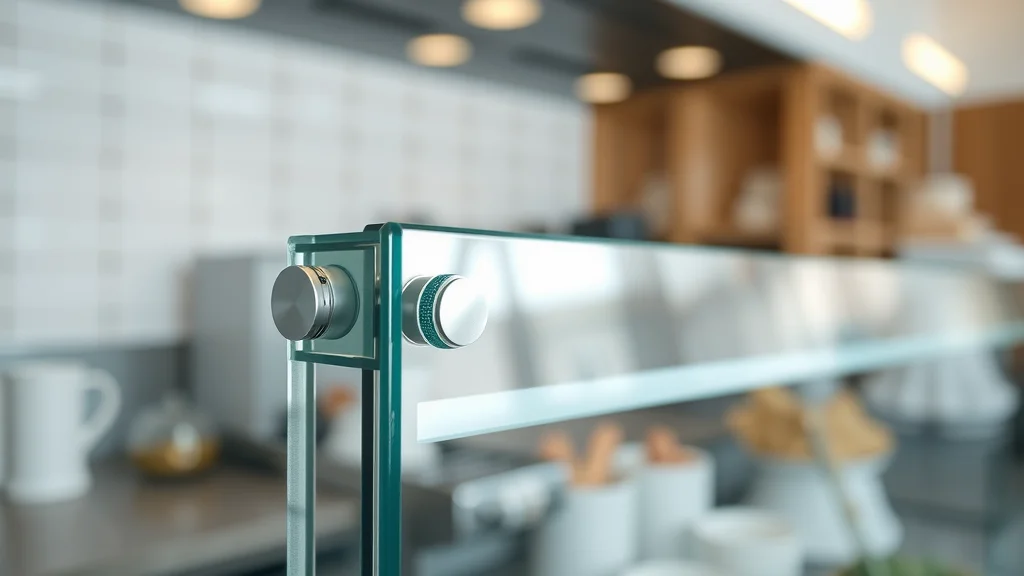

Sneeze guards serve as critical barriers in food service and public spaces, but not all are built—or engineered—with the same purpose in mind. The best sneeze guards combine function, strength, and minimal visual intrusion, elevating the user experience beyond simply meeting regulations. Modern high-performance food shields, such as clear tempered glass panels and UV-bonded systems, bring innovation to traditional counter top installation. By rethinking how sneeze guards look and work, the market moves away from blocky, hardware-heavy setups and into sleek, almost invisible protection zones.

When the conversation shifts from “just any shield will do” to thoughtful engineering, critical issues come into play: how far can supports be spaced? Will the sneeze guard visually fragment your serving area? Poor choices can mean cost overruns, more cleaning headaches, or even unsightly obstructions that turn guests away. For professionals and planners unfamiliar with how modern sneeze guard systems differ, failing to recognize these design distinctions leads to barriers—literal and figurative—to operational success. Recognizing the essential attributes of advanced glass divider systems arms decision-makers with the knowledge they need, making every installation a long-term asset instead of a liability.

Why Innovative Sneeze Guards Are Transforming the Customer Experience

Insights from industry leaders reveal that advanced sneeze guard models—engineered for both beauty and function—are changing the way service environments operate. Leading providers build upon the philosophy that a “clean fresh look matters,” using tempered glass and UV-bonded joints to create an all-glass appearance with minimal visible hardware. This design approach not only improves aesthetics but also keeps the protective barrier unobtrusive, offering customers clear sightlines while maintaining optimal hygiene. By using supports that can span up to 84 inches apart, these sneeze guards eliminate the need for disruptive middle posts that previously cluttered counters and divided workflow, delivering an open, welcoming service line.

Efficiency is also a built-in feature. The modular, engineered systems reduce the number of supports required, which translates into not just cost savings, but a simplified installation process and a sleeker end result. Fast turnaround—sometimes as quick as shipping in 48 hours—empowers businesses to keep projects on schedule, especially when grand openings are on the line. Whether for a small prep table or a sprawling multi-bay buffet, modern sneeze guards meet the demand for both rapid deployment and custom solutions, proving that smart design ultimately means better service and satisfaction.

Flexible Solutions for Every Setting: Customization and Cost Control in Sneeze Guard Systems

One of the greatest pain points for managers and operators has always been balancing customization with budget. Contemporary sneeze guard systems embrace flexibility—offering a wide variety of configurations from full-service stations to self-service islands and partitioned counters. These options, paired with tailored lengths (from 12 inches all the way to 168 inches), allow users to cover exactly the space needed without excess. Select product lines even provide etched glass designs, carved logos, and integrated LED lighting, bringing bespoke branding and modern lighting schemes to any environment.

By reducing the number of supports—sometimes by half compared to traditional designs—advanced sneeze guards turn cost control from a challenge into a strategic advantage. This engineering enables operators to shield large areas with fewer materials and less labor. Whether managing a new build or retrofitting existing counters, businesses find significant savings over time. The ability to cover expansive serving areas with end supports only—not cluttered by costly or ungainly middle posts—represents both financial and visual progress for the industry.

Speed and Reliability: Solving Last-Minute Sneeze Guard Installation Problems

Grand openings and remodels often run right up to the wire, leaving little room for error when it comes to safety compliance and visual impact. Waiting weeks for custom glass or specialty parts has historically delayed countless projects at a critical time. Leaders in food shield manufacturing redefine the game by keeping a ready inventory of popular sizes (from 24 to 84 inches, in 6-inch increments), ensuring that most configurations can be built and shipped within just 48 hours. Even fully customized, tempered glass units are typically ready in a mere five to seven days.

This rapid turnaround supports business continuity without adding stress to already tight schedules. Operators can trust that their sneeze guard solution is not just functional, but finished on time, without resorting to temporary measures or compromising on design. In the fast-paced world of service environments, where first impressions and safety are paramount, this blend of speed and reliability makes all the difference.

Minimalism Meets Maximum Impact: The Evolution of Glass Dividers in Public Spaces

The visual language of modern public spaces increasingly favors open, airy environments that feel safe and inviting. Advanced sneeze guard systems contribute to this trend by employing clear, tempered glass supports and seamless, all-glass looks. By avoiding bulky hardware and metal posts, these glass dividers create a sense of openness, reduce clutter, and support better interactions between staff and customers. Innovative partition models span significant distances without need for interruption, creating functional zones that enhance rather than disrupt atmosphere.

The result is a subtle, yet powerful, architectural feature: a sneeze guard that’s as protective as it is visually neutral. Businesses benefit from a professional presentation, less visual noise, and the knowledge they’ve invested in a solution that values both form and function. As the expectations for clean, modern design rise, these innovations shape not only safety protocols but the entire customer experience.

The Engineering Philosophy Behind Modern Sneeze Guard Design

At the heart of next-generation sneeze guard solutions is a willingness to rethink every detail—from structural engineering to rapid order fulfillment. This philosophy is anchored in the principle that every customer deserves a clean, attractive, and safe environment. By deploying CRY and CRG lines that maximize glass visibility and minimize hardware, manufacturers build sneeze guards with precise engineering standards—capable of spanning wide areas securely, while clearing visual sightlines and reducing the need for frequent cleaning or costly mid-line supports.

Robust internal testing governs every length, thickness, and support specification, ensuring not just regulatory compliance but lasting durability. Careful inventory planning supports the fast-paced nature of commercial food service, anticipating customer needs with stock sizes and made-to-order solutions. Ultimately, these choices reflect a mission-driven approach: to bring the best of modern design, efficiency, and adaptability to every project, large or small.

The result is a sneeze guard system that exemplifies innovation—delivering on both aesthetic ambition and practical necessity. Through engineered strength, design flexibility, and a dedication to timely service, today’s sneeze guard solutions stand as quiet sentinels of public well-being, built on the foundation of technical expertise and thoughtful care.

When Customers Get It Right: The Difference Quality Sneeze Guards Make

Across food service and public installations, those who choose advanced sneeze guard solutions discover first-hand the difference careful engineering and design can make. Though every scenario is unique, the outcomes typically speak for themselves: reduced installation headaches, streamlined workflow, sharper aesthetics, and greater customer trust. While specific customer reviews are not available for quotation, industry feedback consistently highlights the dramatic improvements—both practical and perceptual—that well-designed sneeze guards deliver.

[Awaiting review: Real customer stories will be highlighted here when available, offering firsthand perspective on the problem-solving power of modern sneeze guards.]

The journey from outdated, cumbersome food shields to sleek, efficient protection demonstrates a commitment to progress and professionalism. Those who take the step to modernize their sneeze guard approach consistently report that it pays dividends in efficiency, appearance, and customer confidence. As more environments raise their standards, taking action becomes less about compliance and more about delivering an outstanding experience for everyone involved.

Moving Beyond Barriers: What Modern Sneeze Guard Design Means for Your Business

As the expectations of public spaces and service environments grow, so too does the need for protective solutions that are as attractive as they are effective. The latest advances in sneeze guard design—combining robust engineering, all-glass minimalism, and rapid delivery—set a new standard for safety and style. Companies pioneering these upgrades demonstrate a clear commitment to efficiency and excellence, making the installation process and end result virtually hassle-free.

With sneeze guard systems that prioritize unobtrusive beauty and real-world utility, business owners no longer have to choose between compliance and customer experience. Every project benefits from the thoughtful philosophy and practical strategies that define today’s leading providers. As this article has shown, the right sneeze guard does more than prevent problems—it actively supports environments where safety, speed, and satisfaction go hand in hand.

Contact the Experts at Glass Divider

If you’d like to learn more about how sneeze guards could benefit your business or public space, contact the team at Glass Divider.

📍 Address: 4865 Warehouse Way, Cummings, GA

📞 Phone: +1 408-844-8335

🌐 Website: https://www.glassdivider.com/

Glass Divider Location and Hours of Operation

🕒 Hours of Operation:

📅 Monday: 5:00 AM – 2:00 PM

📅 Tuesday: 5:00 AM – 2:00 PM

📅 Wednesday: 5:00 AM – 2:00 PM

📅 Thursday: 5:00 AM – 2:00 PM

📅 Friday: 5:00 AM – 2:00 PM

📅 Saturday: ❌ Closed

📅 Sunday: ❌ Closed

Add Row

Add Row  Add

Add

Write A Comment